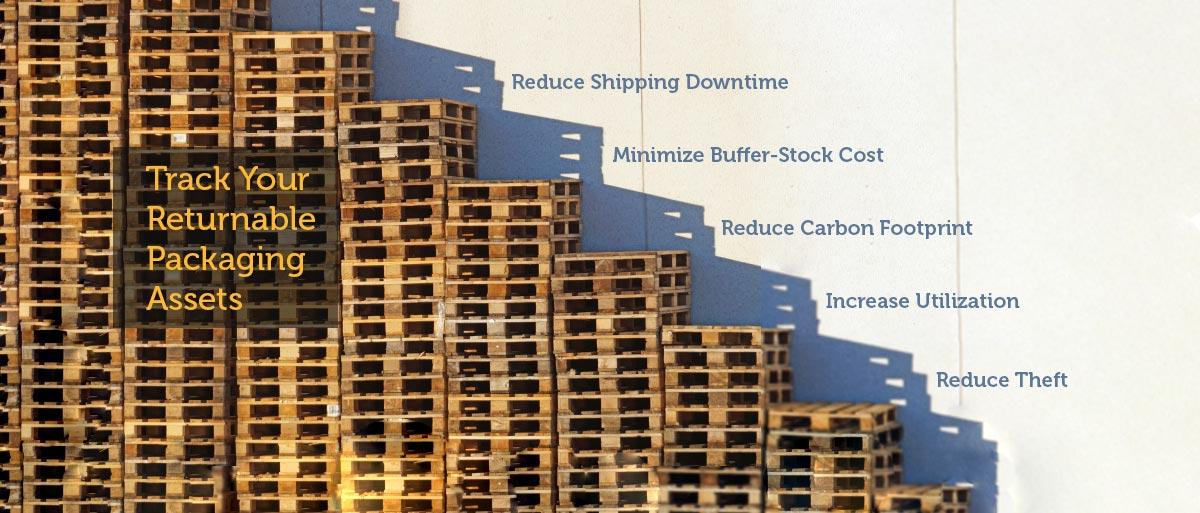

In the world of logistics and supply chains, chances are almost everything that products are moved ON or IN RTI's such as trays, pallets, crates, tubs, bins, or containers.

Returnable Transport Items (RTIs) are packaging materials that are used more than one time. There are several billion of these supply chain assets deployed across the world.

Each year, anywhere between 10% - 40% of the RTI's vanish without a trace. They break down, get lost, get stolen, or just sit idle somewhere because they've been forgotten.

Returnable supply chain assets don't come cheap either. While single-use RTI's cost as little as $20, most returnable assets cost between $200-$5000 per unit, depending on the industry, use, and customization. But who cares about a $20 pallet when there's $200,000 worth of products on it. Yet, purchasing pallets and accounting for their depreciation has a noticeable impact on a company's cash flow, its balance sheet, and factors into the Total Logistics Cost (TLC) when looking at it in terms of volume.

The problem with RTI's is that they're not always used to their fullest potential. While they're supposed to be returnable, more often than not, they don't find their way home. They're difficult to track, especially in open-looped supply chains, where reverse logistics is a hassle and it's almost always impossible to know which of your users is losing, or even damaging your assets.

Why bother with tracking RTI's when they're so easily replaced? Because a missing pallet could be the monkey wrench that brings your perfectly streamlined supply chain to a screeching halt.

Expenditure on new RTI's (and their repair and replacements as well) is a sizeable investment, with companies routinely spending between 10% - 20% of their annual supply chain budgets just to replace missing assets.

It goes without saying that shipping assets such as pallets, crates, and bins have significant strategic value to justify the investment in tracking them. Here are six reasons why you should set up your RTI tracking system.

1. Manage Your RTI's Better

The modern day supply chain is complex, with millions of shipments handled at a high speed. And yet, a number of links in those supply chains still employ manual record-keeping, tracking, and auditing. The visibility that RTI tracking brings, will help improve efficiencies in areas such as:

Identifying Losses

RTI tracking will help you spot those black holes. You have to understand where your assets are going and how you're going to get them back.

Unquestionable Accountability

You will be able to handle faults (and defaulters) in your supply chain better if you can pinpoint flaws without resorting to assumptions and accusations.

Balancing the Books

Supply chain assets are, in fact, assets, and that's reflected in a company's books. The loss of these assets shows up as losses in the company balance sheet. It will improve your ability to log inventory write-off and anticipate the need for reserves or replacements.

2. Maximize the Return on Investment from Your RTI's

With RTI's getting damaged, lost, or simply rerouted incorrectly, shrinkage could be hitting 20% -30% annually. RTI's represent an investment, and if they aren't utilized to the full extent of their viable lifetime, you're not getting what you've paid for. Tracking your shipping assets will help you tackle:

Utilization

Don't let your assets turn into Non Performing Assets (NPAs), and definitely make sure nobody else is making the most of your investment.

Theft

There is a sizable market for reusable containers, with resellers, recyclers, and 'pallet pirates' profiting from companies that don't keep an eye on their RTI's.

3. Minimize Buffer Stock Costs

RTI's are usually over-stocked because there's a fear of running out during peak shipping periods. Besides, re-ordering a pallet is simpler than hauling one back from your own warehouse that's a miles away. This increases the overall level of inventory and slows down circulation. Optimizing your RTI utilization can be a major cost-reduction driver.

By tracking your RTI's real-time, you can ensure none of your RTI's are sitting idle, reducing the need to maintain emergency reserves. You don't have to wait for anyone to do a manual audit. This reduces both the time needed to take stock of inventory, as well as increases the speed at which you can spot shortages.

4. Reduce Lag or Downtime in Your Shipping Process

When it comes to running a tight supply chain, you need to have RTI's around. Tracking your RTI's will tell you where they are, or at least allow you to find them quickly, because that ultimately affects your throughput and things such as:

Holding Time

A shortage of supply chain assets could hit shipping, operating, and holding costs. Avoid that while reducing your need for excessive buffer stock.

Shipping Time

The less time your goods spend in a warehouse waiting for a pallet or crate, the faster they're going places.

Recoverability

Recovering your returnable shipping assets is the easiest way to make sure your shipments aren't held up due to a shortage of shipping assets.

5. Pooling RTI's

By using a pallet pooling network, the expenses of purchasing, maintaining and replacing pallets is reduced, and it helps supply chain managers limit their overhead, even going so far as enabling predictive asset cost-control within the supply chain.

Most pools operate through a "like-kind exchange" system (which sometimes include vendors as middlemen) where companies with similar requirements get back an asset similar to the one they shipped out.

While this arrangement sounds good in theory, you'll probably feel differently if the replacements you're saddled with look like they've seen more of the world than you ever will. Plus, if you need to track usage to improve billing accuracy, then tracking your RTI's is just what the doctor ordered.

6. Make Your Supply Chain Future-Proof

There's a growing emphasis on accountability, environmental responsibility, and enhanced responsiveness to improve efficiency and customer service in supply chains across the world. Tracking your supply chain assets will play a big part in realizing these goals. Through RTI tracking and shipment monitoring solutions, supply chain managers will be better able to cope with:

Greener Logistics

Through the efficient use of returnable and reusable transport items, supply chains can do more than reduce their operational costs, they will also reduce their carbon footprint. The amount of energy and resource it takes to recall and recirculate a RTI is less than what you'd need to recycle a disposable asset, and far less than what you'd have to expend to create a new reusable shipping asset.

Big Data

By tracking your RTI's, you're accumulating valuable data that could be used to streamline and optimize your supply chain. You don't need to wait till you've got a statistically significant set of data to begin realizing your returns either.

If you're leasing or renting a very high percentage of the returnable shipping assets in your supply chain, you can use the data to create more accurate invoices and spend forecasts, even going as far as boosting your profitability engine through enhanced efficiency.

Eccentric Customer Expectations

Players like UPS, FedEx, and Amazon are pushing the limits of what a supply chains' last-mile can pull off, and there's a growing demand for more responsive supply chains that can handle smaller amounts of goods at higher frequencies. This will put an insane amount of pressure on supply chain managers to operate lean yet resilient supply chains that can cope with wild fluctuations in demand and variable shipping asset supply. Deploying an excellent tracking and retrieval system is the only way logistics players will be able to reasonably cope with such variables without drowning in huge shipping asset safety stocks.

Conclusion

RTI tracking is not just a nice-to-have capability—it's become essential for maintaining competitive advantage in today's complex supply chains. The benefits are clear: better asset management, maximized ROI, reduced costs, improved efficiency, enhanced pooling capabilities, and future-proofed operations.

The investment in RTI tracking technology pays for itself through reduced losses, improved utilization, and better operational control. Whether you're dealing with pallets worth $20 or specialized containers worth thousands, proper tracking ensures you get the maximum value from every asset in your fleet.

Ready to transform your RTI management? Contact Posito to learn how our asset tracking solutions can help you gain complete visibility and control over your returnable transport items.